-

What's New

-

This section of the web site has been organized in chronological order, with the most recent progress and commentary first and working backwards to when we moved into the house. More photos and other information is contained in the other sections of the web site.

December 2023 / January 2024 | CPR Boundary Substation mock-ups

Over the years we have added commercial models as placeholders for several mainline stations. Recently, a decision was made to remove these and build some mock up buildings based on the specific prototype structures. This involved research of the actual prototype buildings for which we located numerous photographs and some relevant plans.

In conjunction with these efforts, one of our regular crew offered to produce 3D printed windows and doors for these buildings since no commercially available products would be satisfactory. -

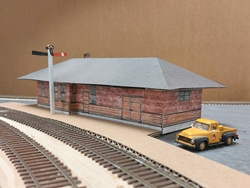

South Slocan

-

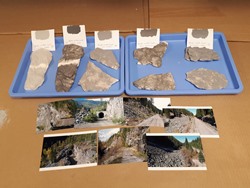

This location is where the Slocan Subdivision branchline joins the Boundary Subdivision mainline, and a fairly modest station existed there until it was removed in the late 70’s. Working with a poor CPR plan and a bunch of photographs, I prepared scale plans of the elevations of the building. These were reduced to HO scale and glued to cardboard. Next, they were colored with pencil crayons, cut out, and reinforced with strip wood bracing. One unique thing on this mock up was the use of brick paper products from Clever Models ( http://clevermodels.squarespace.com ) to represent the insulbrick that was on the upper section of prototype building walls.

Here are a couple photos of the completed mock up;

-

Castlegar

-

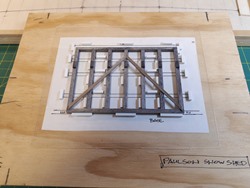

This location is where the Rossland Subdivision branchline to the Cominco Smelter joins the Boundary Subdivision mainline. Here, there is a unique station that was built by the predecessor to the CPR; Columbia & Western Railway. I was fortunate to have copies of the prototype plans for this building and HO scale CAD files prepared by a friend. Both had inaccuracies relative to how the Actual station existed in my era, however they were extremely helpful regardless. The building is a heritage building and hos been relocated and preserved – so, a friend who lives close by did some field measuring to verify discrepancies between the documents and the actual building.

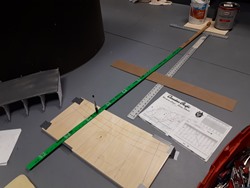

Because this is just a mock up, it was decided to simply print the CAD drawings on heavy cardstock to produce the mock up for now. It was built using the same basic technique as the South Slocan station, except that the roof areas were colored using pan pastels because the white cardstock was too glaring.

This is a complicated building, and constructing a mock up gave me helpful insight into the challenges I would face when constructing the final model.

Here are a couple photos of the completed mock up; -

-

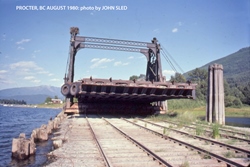

Procter

-

This location at Procter is located along the Nelson Subdivision where the Kootenay Lake barge operation had a three track transfer slip. In the early years of operation, this was a very busy junction necessitating a larger station that the other locations. It also had a residence annex on the rear for the agent.

We have many excellent photos of this building, but no specific CPR plans. However, it was determined that the building was an enlarged and slightly modified version of a CPR Standard #4 station for which we did have CPR plans.

Therefore, by using the photos and CPR plans, again I prepared HO scale drawings of the wall elevations. The mock up building was constructed using the same general techniques as the South Slocan station.

Here are a couple photos of the completed mock up;

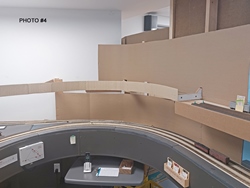

November 2023 | CPR Boundary Subframing & back Drop Mock-Ups

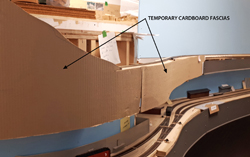

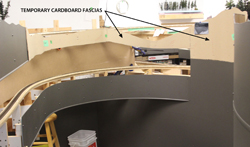

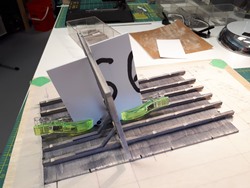

One of the challenges to a multi-deck layout is that it is often analogous to a three dimensional puzzle. This is the case where the South Slocan and Castlegar areas back on to each other on opposite sides of a peninsula. In addition, the track from the Rossland staging yard emerges into Castlegar at this same location. There is also some consideration required for the future upper deck areas that mirror the geometry on the lower deck.

We were also beginning to plan the scenic landforms for the areas in, and around South Slocan which are also affected by physical geometry of this entire area.

So, like many challenges faced during the construction of the layout, it was decided that some mock up framing and backdrops would be helpful.

Following below are a series of progressive photos just to provide a visual of what we accomplished. It was not pretty, but it is impactful.

Here is the Castlegar side;

Here is the South Slocan side;

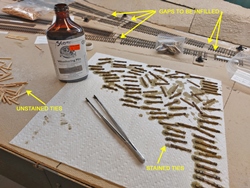

October 2023 | CPR Boundary Subtie infilling; nelson yard

The intent is to keep infilling the gaps in the flex track and commercial turnouts that are used on the layout. I remind myself that I should do this as I install the track, however, I usually “convince” myself that I will get back to it later. Of course, later often is years later!

This is one of those small tasks that can be picked away at when short periods of time present themselves. There are two “tasks” that need to be done. The first is to prepare the ties that will be needed and the second is to install the ties.

The infill ties are all commercial wood ties from various manufacturers, some of which are no longer in business. I sand them down to various thicknesses and create notches in them to allow them to slide beneath rail joiners, while keeping the upper surfaces in the same plane as the adjacent plastic ties. I am also fortunate to have some longer “switch” ties that a friend milled down in thickness to suit some different conditions. These are cut to length to suit specific requirements.

These ties are all stained or painted to sort of match the color of the surrounding plastic ties. All the track gets airbrushed later, so the initial color needn’t be too accurate. It’s just to diminish the visual disparity that would exist if the infill ties were not colored.

Here are some progress photos;

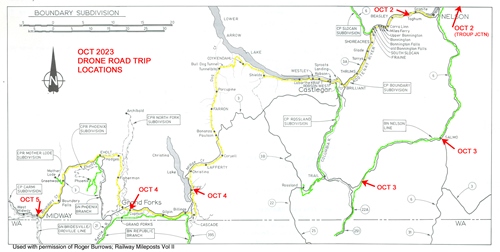

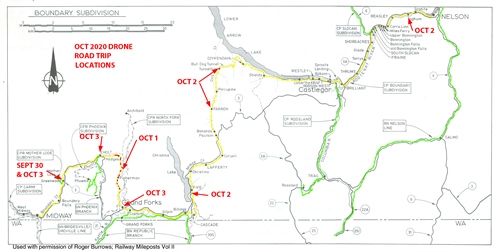

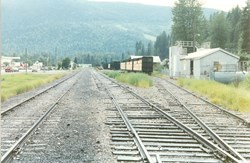

October 2023 | CPR Boundary SubDrone Research trip

In early October, I headed off on my fourth drone research trip covering the areas that I model. This was the third time I used my own drone. The extra batteries I purchased last year proved indispensable this trip due to the heavy winds I encountered at some locations.

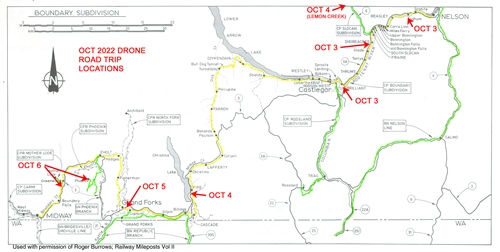

Prior to the trip, I marked up a map of the Boundary Sub area with potential locations and what I wanted to capture. I then developed a travel plan that spanned five days and covered a couple thousand kilometers. On this trip I was able to remain on public roads and did not need to drive onto the abandoned grades as I have done in the past. I also did a lot more ground level photography with my SLR camera due to airport flight path restrictions in some locations.

As noted in my previous posts concerning the use of drones, I am very careful where I fly, and I obtain permission where appropriate to do so.

Here is a map of the Boundary Sub with the locations where I did photography noted on it.

Below is a sample of some of the still photos taken. The videos are too large to include here.

You can view more of my drone photos in the Prototype Photos section of the web site.

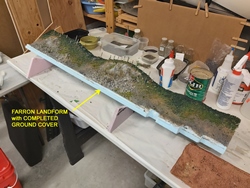

August & September 2023 | CPR Boundary SubFarron foliage work

The Fall 2020/Summer 2021 post showed the progress of the Farron siding shelf area of the layout. While the work was nowhere near complete, it looked much better than the white plaster landforms.

Over the balance of 2021 through to early 2023 we continued progressively working on the scenery and structure installation in this area of the layout. The 24 foot long backdrop was completed in July 2022 by Rene based on my drone photos of the area.

Once satisfied with the backdrop and ground cover, it was now time to “finish” this section of the layout by completing ballasting, adding static grass, planting trees and other foliage.

Here are some progress photos, starting with the most recent and traveling back in time.

August 2023 | CPR Boundary Subcabin tree building trip

Well, on a layout the size of, and location of the Boundary Sub, there is a need for a lot of trees! Even with the narrow shelf type design utilized along numerous areas, we still need trees, and then – more trees and then – more trees!!

While we have a large inventory of trees, many more are required, so we build some when the urge or opportunity hits us. The 2023 summer presented an opportunity to spend a few days at our cabin in the mountains with our friends; Ken & Patty and collectively built a bunch more trees while we were there. Definitely more enjoyable building them with friends, sitting on the deck looking out over the river on a beautiful summer day.

We do a mixture of furnace filter trees and also use the commercial trees I purchase in bulk from the Philippines. (See also the May 2020 What’s New post).

We think these are probably the best furnace filter tress we have even done. We tried very hard to avoid the layered look of some of these type of trees, and utilized probably 20 different color combinations.

Here are a few photos of the “production line & crew" and some results.

May to July 2023 | CPR Boundary Subloco qa & decoder pro work

One of my biggest weaknesses is electronics! Over the years, I have been very fortunate to have several good friends who can skillfully do decoder installation and programming work on my ever-increasing fleet of locomotives.

In April this year, during an Op session (of course) my LENZ command station failed, and the layout shut down. Much longer story here, however, we had a back up Command station and installed it and reset a bunch of stuff, all of which was WAY over my head.

This taught me that I need a better understanding of decoders and programming, so I bit the bullet and installed Decoder Pro on my laptop. With the help of several good friends, who had great patience, we plugged away at redoing all the locos. In the process, we speed matched sets, and set the locos up so their prototype speeds closely matched what the CVP T5000 throttles showed on their LED screens.

We have operated the layout several times since this work was done and it has revealed that there are still some “problem” locos, so we are continuing efforts to get them working better. I also have some very old decoders which are well overdue for replacements, so that will be done as well.

Here are a few photos of the fleet being worked on with Ken and Anthony investing a lot of time with me on this project. I am extremely grateful for their help and never-ending patience!

March & April 2023 | CPR Boundary SubKootenay River scenic base rebuild

Over the years, I have watched many model railroaders install very realistic static grass on their layouts. So, I decided it was time for me to attempt this skill. While there are lots of YouTube videos on this topic (some good, others not so good), I personally prefer hands on interactive learning.

So, I reached out to a friend who does great static grass work and recruited him to teach me. A couple members of my crew learned of this upcoming tutorial and asked to join us. We had three able bodied students, all with different applicators, and our teacher Marc.

We basically just set up some tables in my garage and brought all our collective materials together. I made several Styrofoam bases to experiment with. I also have a 12” x 48” diorama that I built for a clinic years ago, so decided I might as well try this out on some thing that would be used in the future. After practicing a lot and creating numerous mixes using different colors and lengths of static grass, I was confident enough to apply some to the layout. I used Woodland Scenics, which I find too uniform in color, with War World Scenics static grass which, in my opinion, is way better for what I am trying to create. Downside is they are based in the UK and I have not found a North American distributor yet. So, shipping charges to Canada are outrageous!

I chose some random locations along the upper deck where the scenery was “complete” and proceeded to try it out. While not always successful initially, I was pleased with the efforts as I continued to work. I actually went back over some of the first areas and added some more to enhance the look. Static Grass really adds a very fine and subtle scenic element and stands out in photos. Kudos to the person that invented static grass.

Here are a few photos that give an idea of how it is coming for me.

November & December 2022 | CPR Boundary SubKootenay River scenic base rebuild

In the Fall 2018 post we reported on how we removed “temporary” crumpled paper scenery and replaced it with the more traditional cardboard strips and plaster cloth. Well, that ended up also being “temporary” as well!

After completing extensive drone photography of this area, it became apparent that the current plaster landforms di not accurately capture the topography of this area. So, the plaster work was completely removed. Then, grey Styrofoam landforms were created and shaped to reflect the character of the actual site. The landforms were extended eastward towards the new South Slocan siding as well.

Here are a series of photos that show the removal of the previous plaster landforms and the creation of the replacement grey Styrofoam landforms;

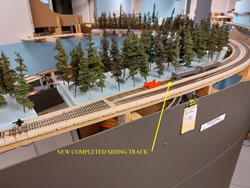

Fall 2022 / Winter 2023 | CPR Boundary SubSouth Slocan Siding Addition

One of the key feedback learnings from my RMMBC 2022 Op sessions was that South Slocan REALLY needed a proper siding. There is a lot of traffic between Nelson and Castlegar on the layout, and this was the only location where meets could be scheduled. So, I promised the home team that I would make this a priority, little did I anticipate how much work it would be!

This project involved removing & modifying about 15 feet of completed fascia, extending the cantilevered framing along this same 15 foot length. Adding many new track feeders, modifying several commercial turnouts, cutting into the existing mainline track at two locations, and installing the new 23 foot long spline roadbed system and track.

As of this writing, I still need to modify/rebuild some turnout control panels and install several new powered switch machines. As well, this area will get our grey Styrofoam landforms too.

October 2022 / February 2023 | CPR Boundary SubDrone REsearch Trip

In early October, I headed off on my third drone research trip covering the areas that I model. This was the second time I used my own drone. From experience with previous trips, I decided to purchase several more batteries since they get depleted fairly quickly, especially in windy conditions – which the BC mountains tend to be!

Prior to the trip, I marked up a map of the Boundary Sub area with potential locations and what I wanted to capture. I then developed a travel plan that spanned five days and covered a couple thousand kilometers. On this trip I was able to remain on public roads and did not need to drive onto the abandoned grades as I have done in the past.

As noted in my previous posts concerning the use of drones, I am very careful where I fly, and I obtain permission where appropriate to do so.

Unique to this trip was a confrontation with a bird! I wasn’t aware of the nest in a tree across the river from where I launched, however, as I approached the opposite bank an ear splitting screech came from the trees and a large bird flew directly at the drone! I had read about others who had these experiences, sometimes ending with the destruction of the drone and harm to the wildlife. I immediately dropped the drone down closer to water level and retracted it rapidly to reduce the perceived risk to the birds. After that, I chose how I approached the bridge I was filming with respect for where I determined the nest was located. Glad I didn’t have to wade into the river to fetch a soggy drone!

Here is a map of the Boundary Sub with the locations where I did photography noted on it.

Below is a sample of some of the still photos taken. The videos are too large to include here.

-

You can view more of my drone photos in the Prototype Photos section of the web site.

-

January 2022 / February 2023 | CPR Boundary Sub

Porcupine Siding Relocation & Grey Styrofoam Landforms

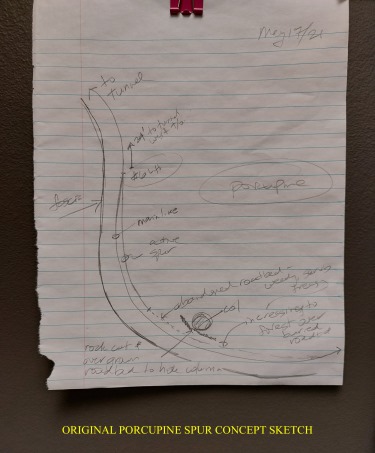

The original concept for the Porcupine location (just east of Farron) was to construct a poorly maintained spur that was the remnant of the original siding. The spline and roadbed were installed for it many years ago and then this project drifted lower on the “to-do” list.

Early in 2022 it occurred to me that this spur would be too close to the east end of the Farron siding, so I decided to rip out the original roadbed and construct a new one further east and with the turnout at the east end instead. This work would be completed in conjunction with the installation of new Styrofoam scenery landforms eastward from the end of Farron towards the site of the Porcupine fill.

-

Back in May 2021 I developed this rough sketch of what I thought the Porcupine spur location might look like.

Back in May 2021 I developed this rough sketch of what I thought the Porcupine spur location might look like.

The actual work commenced in February 2022 with the removal of the old roadbed and the construction of the new roadbed for the Porcupine spur. We used the established method for the spline and roadbed. The mainline was cut to accommodate the modified Shinohara turnout that would connect to the new spur track. We used Micro Engineering code 70 flex track for the spur. It was modified to spread the ties out and look rattier.

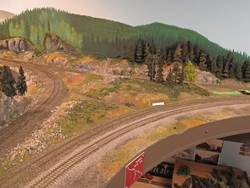

At this point, the project took a hiatus until June, when the work and construction of the Styrofoam scenic landforms along this large curve resumed. This track is a dominant scene as you enter the train room and is at about 64” above the floor. After reviewing our large photo & drone video archive of that part of the abandoned line numerous photos were selected to guide the development of these scenes. These photos will also guide our selection of colors and textures, like has been done in other areas of the layout.

At this same time, I was given several sheets of a different type and color of Styrofoam. It is higher density than what I had been using, but, more importantly – it is Grey! Dupont is the manufacturer. The neat thing is that even in the contoured state, before any scenic materials are applied, it looks way better than the typical blue or pink Styrofoam!

Cardboard templates were created for the required individual pieces and laid out on the foam sheets to use it as efficiently as possible. A variety of tools were used to cut and shape the foam into the desired shapes using techniques utilized in previous areas of the layout. The landforms were also marked with proposed rock casting locations with a black marker.

At the time of this post, there has been no detailed scenery work done on any of these landforms, however, they remain visually effective for the time being.

4th Division, PNR YouTube Videos

Early in 2021, I was approached by the team of 4th Division PNR/NMRA members that were producing their excellent Zoom presentations during Covid. After a little arm twisting, I agreed to do a Layout Tour presentation, and subsequently, also agreed to do a brief Layout Ops Overview presentation as well.

They were recorded and have been posted both on my YouTube site and the 4th Division PNR site. Here are the links if you are interested:

CPR Boundary Sub Layout Tour 2021;

- Scott Calvert YouTube Link; https://www.youtube.com/watch?v=P4cYQ4B0Zgg

- 4th Div YouTube link; https://www.youtube.com/watch?v=nan_8OIVhdg

CPR Boundary Sub Layout Operations Overview 2021

- Scott Calvert YouTube link; https://youtu.be/VhU8bXQmokc

- 4th Div YouTube Link; https://www.youtube.com/watch?v=eHrMAg42fyQ

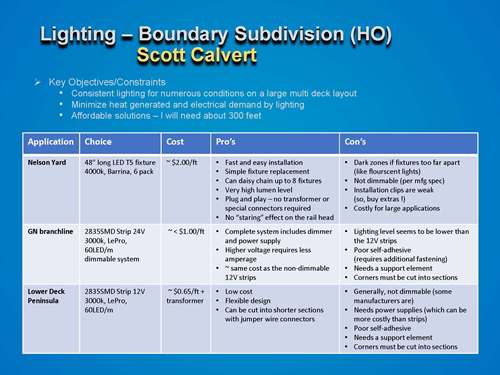

April 2021 | CPR Boundary SubNelson Yard LED Lighting

After conducting research into LED lighting, I opted to install commercial 48” long LED T5 fixtures manufactured by Barrina along the entire 40 foot length of Nelson yard. They are 4000k fixtures which works well with the other lighting in the room. I purchased these through Amazon Canada, and when you consider all costs for LED lighting installations, they were cost and time competitive.

I wanted something that was going to stand the test of time because I didn’t want to face the prospect of removing and replacing lighting over my main yard! This system is a “plug & play” system, it literally took me a morning to install all 8 fixtures, hook them up and test them – and I was done! Here is a copy of the Installation Guide for these fixtures;

Unfortunately, my upper deck fascia did not visually obscure the LED tubes satisfactorily, so a small section was added along the bottom edge of the existing fascia.

-

Click the image below to see more on the lighting project.

-

-

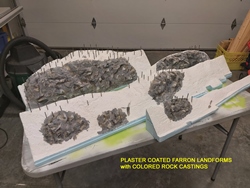

Fall 2020 / Summer 2021 | CPR Boundary SubFarron Landform SCenery

Our previous Spring 2020 Post featured the beginning of the scenicing process for the Farron siding and wye area. At that time, all the basic landforms were created, sculpted, and had received the primary coats of plaster and rock castings. Essentially, it looked like a winter scene!

In September 2020, we resumed work in this area. First up was to create and scenic the landform that rests within the wye area and the adjacent landforms. These were needed first because this area was used for the photography of the CPR water tank used in a November 2021 Railroad Model Craftsman article authored by Patrick Lawson in the.

Then, the landforms previously created in the spring were scenicked using the same techniques utilized for the previous scenery landforms on the layout.

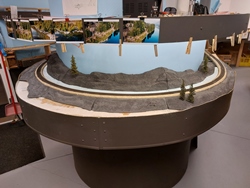

And, for fun, my son flew one of our drones INSIDE the train room and took these photos. Safety is paramount when flying drones indoors, and he is a fully registered and licensed drone pilot.

Pending future work to complete this area include; backdrop painting completion, installation of trees & foliage, adding various misc. detail items, and static grass applications.

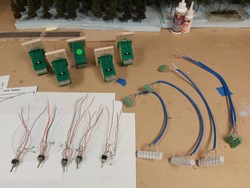

Fall 2020 / Early 2021 | CPR Boundary SubFarron switch Machines & Control Panels

Farron is the highest of the two summits on the prototype Boundary Sub. and mine sits at 67” above the floor. I am 6’-2” in height which makes it at my eye level, but too high for most model railroaders to view comfortably. So, it was decided to power the switches at this location with Tortoise machines and fabricate custom made fascia mounted control panels.

This work spanned many months and involved several cardboard and styrene panel mock ups, and some test wiring. I mass produced most of the assemblies at the work bench to make the in-situ work as easy as possible. The ultimate work included the installation of 11 switch machines and 4 control panels and was completed in February 2021.

The panels are custom cut Lamacoid material made by our local Fast Signs franchise based on my design sketches. The burgundy color was chosen to complement the classic CPR paint colors and the lettering is the actual CPR font that I was able to obtain.

November 2020 | CPR Boundary SubFarron Structure & Platform Completion

In the spring of 2020, a mock up of the Farron scene and proposed structures was developed. It was then left dormant while work proceeded on other aspects of this part of the layout. See previous March 2020 Post.

In late 2020 we resumed work in this area as part of the advancement of the Farron landforms and scenery. Work involved creating a removable Styrofoam landform laid out specifically for the cluster of buildings using several prototype photos as a guide. This base was covered with the same basic scenery materials as the surrounding landforms. A hardboard fascia was glued onto the Styrofoam base and painted to match the layout fascias.

As of January 2023, the platform remains removable for photography convenience, safety reasons and for access to the turnouts beyond the buildings. It will receive a random application of static grass and final foliage and trees at the same time the rest of the entire Farron shelf area does.

- October 2020 | CPR Boundary Sub

Drone Research Trip

In the summer of 2020, I purchased a DJI Mini-Mavic drone primarily to use for research along the Boundary Sub. This is a small drone with limited features which made it quite affordable. Although it did not need to be registered due to its light weight, I have taken online lessons on how and where to use it safely and effectively. I am EXTREMELY careful where and when I use it. I also had written permission to fly it on the C&W Trail which includes sections of the abandoned Boundary Sub roadbed.

Here is a map of the Boundary Sub with the locations where I did photography noted on it.

Below is a sample of some of the still photos taken. The videos are too large to include here.

You can view more of my drone photos in the Prototype Photos section of the web site.

- May 2020 | CPR Boundary Sub

Cabin Tree Flocking Trip

Many years ago, a local group of modellers sourced and purchased commercial conifer trees from a supplier in the Philippines. Given the growing demand for trees as the scenery on the layout continues to progress, I placed another order for about 850 trees varying from 1.5” to 8” in height. They come in a rather bright green color, so we flock them with the same six mixes of Woodland Scenics and Scenic Express materials that are used on the furnace filter trees giving them a visual family look.

The trees arrived in a highly compressed state in one cardboard box. I had to slice the box sides apart to get the trees out, and then had to meticulously untangle them. After I sorted them into sizes, I restocked them in a series of boxes. Hard to imagine that “cube” of trees eventually occupied almost 6 individual boxes!

Below are a couple of photos of the boxes, and a couple of the completed trees in a Styrofoam base. Ready for planting!

- October 20220 | CPR Boundary Sub

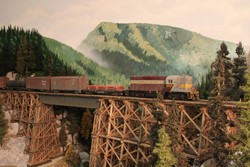

Upper Deck Scenery Continues

Well, getting this section of the upper deck completed has proven to be significantly more work than I had anticipated and I KNOW I have spent too much time on it. Having admitted this – I am still really pleased with the outcome and it has produced several scenes that are quite exciting and do capture the look and feel of the prototype scenes.

The last entry on this topic was in the summer of 2019 when we were working on backdrops and basic scenery shapes. Fast forward more months than I want to admit, and we are almost there in completing this very important 35 ft long stretch of the mainline. This is the most scenery I have done since my previous layout (see the June 2013 issue of Railroad Model Craftsman) was demolished!

And, oh my God do I need a lot of trees! This section which doesn’t yet have all the trees has consumed in excess of 350 trees so far. Serves me right for choosing to model a railroad that passes through some of the most heavily forested parts of British Columbia.

Here are some photos of the almost completed areas. See the Layout Photos section for more photos showing the progression of the work.

- Spring 2020 | CPR Boundary Sub

FarrON Scenery Underway

The Styrofoam scenery landform methods employed for the upper deck over Nelson yard have proven to be very successful, so we opted to continue using them for the Farron siding area through to the Porcupine siding area. See the Winter 2018 / 2019; Phase 3 of the Mainline Continues entry below.

-

In general, the topography of this area is far less rugged than it is through the section over Nelson yard, so preparing the Styrofoam landforms is proceeding more quickly, and it is anticipated to take a lot less effort to complete. This shelf is only 12” in depth to the back wall, except where the buildings are located where it will be about 18”. -

Work in this area also involved installing a backdrop along the 20 foot long wall behind the siding which was needed to cover over the metal shelving brackets mounted to the wall. -

Most of the landforms have been completed using the variety of methods and tools utilized for previous work. As always, this is a messy process so the bulk of the work including completion of the basic ground textures is being done in the garage/shop and not the actual train room. -

All the scenic Styrofoam landforms are shaped and have rock castings and a base plaster coat on them. Although they are now ready for the detailed scenery textures and coloring, this work will now wait until I complete the installation of the switch machines for all the Farron turnouts. It is much easier to do that work when the scenery landforms are not installed. -

Here is a couple of “before” photos looking both east and west along the Farron siding area, and a recent panorama photo that captures both directions.

- March 2020 | CPR Boundary Sub

Farron Siding Structures

Farron is the summit station for the crossing of the Monashee Mountains and was home to the helper locomotives during the steam era. There was a variety of structures located here and in my era several remained in service.

-

Our research is ongoing since photos of this somewhat remote location are not that common, however, we have ascertained which buildings we believe were there in the early 1960’s. Most of the structures were generic designs, although as is typical with the CPR, many of them were not built “exactly” to the standards! -

In conjunction with the planning and execution of the scenery in the Farron area, a mock up was developed with accurate mock ups of the buildings that were felt to be appropriate for this location. They will all be scratchbuilt, and at the time of writing, the 40,000gal water tank is nearing completion by Patrick Lawson MMR, who has been a frequent contributor of wonderfully built structures for the layout. -

Here are a few photos of the construction of the mock up buildings and overall area;

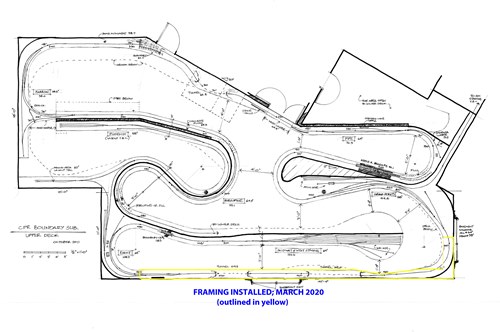

- March 2020 | CPR Boundary Sub

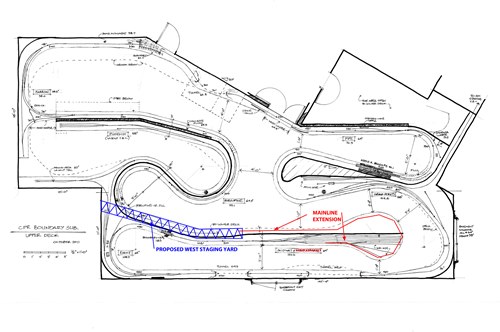

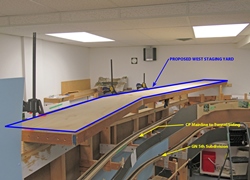

Upper Deck Framing; Grand Forks to Eholt

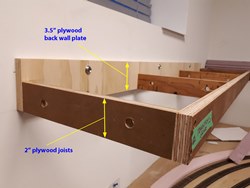

Since the scenery work is typically done by myself, when I have helpers attending my work sessions, I create other projects to capitalize on their availability. After completing the west end staging modules referred to below, we then shifted to the construction and installation of a series of pre-fab plywood modules that would connect Grand Forks to Eholt. This is actually the longest straight section of upper deck on the layout at about 45 feet in total length.

-

Once again we utilized our successful pre-fabricated plywood module framing system for this section. Most of the modules are the typical 12” x 48” long with a few custom sized ones at the narrower area and all have predrilled wiring holes in them. To maximize clearance to the lower deck and provide some depth for the scenery below the upper track, 2” deep joists and a 3.5” back wall plate were used. Because the track grades are 2% on the lower track and a lesser 1.25% on the upper track, we needed to step the modules up at a couple strategic locations along this stretch of framing to maximize clearance to the lower track. -

Like the west staging yard referred to below, this framing will simply remain in place for the time being until more detailed design work is completed and the actual mainline trackage gets closer. Depending on how the next phase of the mainline expansion gets executed, we may remove 3 of these modules and drop the existing temporary west end staging yard modules in their place which will add the locations of Fife and Grand Forks into the layout, and extend the mainline by another 75 feet. -

Here is a layout plan showing the extent of this new framing, and a few photos. The pink Styrofoam pieces indicate the rough alignment of the mainline.

- February 2020 | CPR Boundary Sub

West Staging; Latest Concept

When I designed the layout originally in 2011, I admit I didn't invest much thought into the final west end staging yard design. The initial concept was simply to expand the Midway divisional yard at the west end of the layout to include a bunch of staging tracks, and it was left at that.

-

In the last couple of years, as the mainline continues to progress westward, I have started to initiate planning for the final west end yard. Over the last several years, a couple of concepts have been developed through sketch plans, and subsequently abandoned for various reasons.

-

In late 2019 while wandering around the train room and brainstorming, I revisited the issue of planning the west end staging yard – again, and came up with yet another idea. After sketching up some framing and track alignment concepts and theorizing how the trains would work and scenery might develop visually, we jumped into more detailed design, construction and installation of several of our pre-framed plywood modules.

-

With the assistance of Ken C and John M, we managed to get 3 modules temporarily installed which will hold 7 tracks and with a capacity of about 200 cars.

-

-

Since there are two more expansion phases containing the remaining 180 feet of mainline required to reach the west end staging yard, these modules will remain in place for the time being, while we continue with other priority projects. This allows us to ponder if this will be the actual “final” design.

- August 2019 | CPR Boundary Sub

Completion of Phase 3 Mainline Trackwork

It was imperative to complete this phase of the mainline in time for the bi-ennial Vanrail Operations weekend taking place on Sept 6 to 8th, so we had to really hustle to achieve this objective. As described in previous postings, we were well into the construction of this next section of the layout as the deadline became closer; however, a lot of work remained to do in just a few brief months!

The scope of this project included; completing the construction of the framing modules, constructing the spline roadbed system from the end of the previous mainline up to the location of the relocated staging yard, designing and constructing a vertical lift bridge to span over the room entrance door, preparing and installing all the turnouts and flextrack, installing the necessary bus & feeder wiring, and then testing everything. Before relocating the west staging yard modules, as much work as possible needed to be completed and tested. Much of the work employed the same successful techniques used to date on the layout which certainly helped move things along.

There were some stressful moments; however, with the substantial assistance of Ken C and John M, we made it – barely!

Here are a few progress photos of the work as it proceeded.

-

- August 2019 | CPR Boundary Sub

Temporary Slocan City Module

Over the years that we have operated the layout, I have observed that folks running the Slocan Turn switching train often got frustrated due to the limited amount of track at that location. The design of the layout contemplated another section in the dispatchers room that was to represent Slocan City and the Slocan Lake barge operation. Even though this section of the layout had not yet made it to the top of the action list, I decided I needed to construct at least a temporary section of this future area to provide some relieve to the congestion that occurs there.

So, with only 1 week until the VanRail Ops event, I grabbed a 1ft x 8ft piece of plywood and spent the day designing and constructing this temporary switching area that connected to the South Slocan wye tail track. I reused the temporary cardboard buildings and faked out a barge location for now. While not very fancy, it certainly reduced the problem and folks that were assigned this job during VanRail appeared more relaxed. This section will be removed in the future when the final design is completed for the Slocan City area.

Here are a few progress photos of the work. - Summer 2019 | CPR Boundary Sub

Upper Deck Scenery Continues

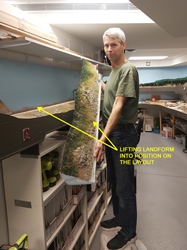

Work on the upper deck scenery continued as long as possible before the need to stop and clean up the layout and uncover Nelson yard to prepare for the test operating session on August 28th, and ultimately the VanRail operating sessions. My thanks go to Rene Gourley who took on the last minute job of painting the backdrop in this area based on the numerous photos I had taken over the years – including numerous drone photos.

The actual scenery efforts were a continuation of the materials and methods we started using on this deck back in the fall of 2018. All scenery landforms are stacked Styrofoam sheets carved with various tools, to which plaster rock molds were wet cast and remaining areas were covered in a plaster seal coat. The rock castings were colored with a variety of diluted acrylic and latex paint colors and the non-rock areas were painted with a base ground coat of latex paint. Then a huge array of scenery materials was applied using many photos as a guide.

The installation of trees and foliage was left until the landforms were placed back in their positions so the height and colors of the foliage could be matched to the painted backdrops thereby creating a more blended appearance.

While not completed, the result of this work was visually impactful and, again, provided lots of learning moments!

Meanwhile, here are a few photos showing some of the efforts to date. Also, please refer to the Layout Photos tab for many more photos of this work to date.

- June 2019 | CPR Boundary Sub

Concrete Tunnel Portal and Liner Castings

One of the key features of the current mainline expansion is the 365 ft long curved Paulson tunnel. While originally constructed as a rock bore in the late 1800’s, in the mid 1940’s both ends of this tunnel were reinforced with concrete portals and liners. In addition, there are few other tunnels on the Boundary Sub. that have concrete portals. While they are all somewhat unique, they do have some geometric similarities. There are no commercial model castings that even come close to emulating the prototypes so I designed a plaster casting mold that had variations in it to capture the shapes of the prototype portals. The mold is lined with rough scale lumber to give the finished castings a formed wood look. In order to create the look of the concrete liners, several castings were sanded and then grafted together to achieve a liner depth that reflected the prototype. In total, I cast 18 castings altogether, which will be sufficient to complete all the Boundary tunnels with a couple of spare castings – just in case!

Here are prototype photos of the two Paulson tunnel portals:

And here are photos showing some of the many steps and resultant castings:

-

- Winter 2018 / 2019 | CPR Boundary Sub

Phase 3 of the Mainline Continues

Further to the July 20, 2018 post below, here is an update regarding the ongoing construction of this phase of layout expansion.

So, after spending a couple days clearing out Nelson yard of all rolling stock, locomotives and structures, the entire yard surface was covered in heavy cardboard to protect it and away we went!

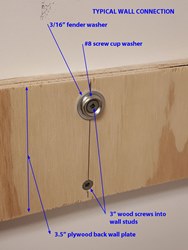

Numerous “module” frames were constructed to carry the mainline over Nelson yard. Other than the back 3.5” high piece, all framing was 2” high – ¾” plywood to minimize the depth. The prefab modules were typically 48” long and were constructed in the garage/shop and then anchored to the walls. This is the standard method of construction for most of the cantilevered framing for the layout. Here are a couple photos of the framing being installed. -

From there we utilized the Styrofoam roadbed templates to establish the track alignment on top of the modules. Once we were satisfied with that, we constructed the spline roadbed system (see Sept 2012 entry below & the clinic presentations in the Techniques tab) along most of the 40 foot length above the yard. This section is on a descending 1.1% grade, which is slightly more than half the prototype grade in this area. Here are a few photos of that part of the work;

-

In an effort to manage the weight of these “modules” we elected to build the scenery landforms from Styrofoam in sections that aligned with the module joints. At this point we (ok – maybe it was just me!) were still thinking that the individual modules could be removed from the walls and do most of the scenery and track work in the garage/shop. After removing and replacing one of the smaller modules, it became obvious that taking them out and putting them back was going to require a lot of realignment to obtain successful re-installations, so, we (ok – it was me) abandoned the idea of removing/reinstalling the modules, but retained the idea of building the Styrofoam landforms separately, also in the shop. This turned out to be a very solid decision and has proven very practical. These landforms were built of stacked foam sheets glued together and then carved with various tools. I tried a hot wire cutter, and was not happy with the fumes or how it actually worked – so, I gave up and used a variety of knives instead. Here are some examples of the work to date;

-

Once satisfied with the general topography of the landforms, they were given a coat of plaster and then rock castings were wet-applied in various places. The landforms were then placed back on the layout and tested for clearances and for visual acceptance. We are working to replicate several scenes along this part of the mainline as photographed on previous trips, including drone photos – see the October 2018 and 2017 entries below. This has been a very iterative process and some landform sections were deemed unacceptable and were salvaged to practice rock coloring on.

Once satisfied with the general topography of the landforms, they were given a coat of plaster and then rock castings were wet-applied in various places. The landforms were then placed back on the layout and tested for clearances and for visual acceptance. We are working to replicate several scenes along this part of the mainline as photographed on previous trips, including drone photos – see the October 2018 and 2017 entries below. This has been a very iterative process and some landform sections were deemed unacceptable and were salvaged to practice rock coloring on.

-

In the midst of this, I decided some more appropriate rock molds were needed, so brought home several dozen rocks to make molds from. This was somewhat disappointing project, and only about half the molds turned out to have the nature of rockwork I was looking for. The natural rocks in this part of the Kootenays are what I refer to as “chunky” and many commercial molds do not capture this type of rock. In any event, we managed to get several good molds, and combined them with the old ones I had and some that were lent to me. We did try the Woodlans Scenics rock molds which have some very nice texture, however, we found they too stiff and not suited for the wet casting techniques to do.

-

We decided to accurately lay out the track centreline on the roadbed next, trim the edges of the roadbed to create the side slopes, caulk all gaps and give the roadbed 2 coats of latex paint. We felt this would be much easier to do without the landforms in place. Here are a couple photos of those steps;

-

Meanwhile, I realized I had not done finished scenery in over 6 years – not since the previous layout was demolished – and it seemed I forgot a lot of what I learned back then! So, I decided I needed to spend time on techniques, coloration etc. on extra castings before applying my efforts to the real landforms. It has been a painful process, with lots of mistakes and less than satisfactory results, however, I think I have learned the rock color techniques now – remember, I am trying to model very specific scenes so what I refer to as “colors and textures” are important. So, with some trepidation, I am now cautiously embarking of rock coloring on the permanent scenery landforms. Here are numerous photos showing some of the efforts to date.

As you can probably imagine, this all takes a fair amount of time considering this section is about 40 feet long and is quite complicated from a scenic perspective. Consequently, the work is still underway, although we are getting close to be completed the Styrofoam landforms and plaster work can conclude in the near future. And, all of this work was undertaken at the same time as the Paulson snow shed – see post below – was being constructed! -

-

So-stay tuned for the next installment where I will hopefully be able to share some more completed scenic photos and backdrop progress!

- February 2019 | CPR Boundary Sub

Paulson Snow Shed Completion

This shed is located in the Paulson area on a 2% westbound grade and is the larger of the two on the Boundary Sub. It was planned for a signature location on the upper deck that is currently under construction and therefore needed to be constructed as part of that extension project.

-

It is located on a curve and is about 165 feet long. I believe it was removed sometime in the 90’s and replaced by an electronic slide detection fence.

-

I wanted to scratchbuild this shed and make it as close to prototype as possible, and was fortunately able to secure some great photos of it taken by the late Dave Wilkie in the 60’s and 70’s. These were very important in providing guidance on what aspects of the shed did not follow the standard CPR design and also its physical condition in my era.

-

I decided to construct the shed in 5 equal tangent sections and to build it upside down – so, first thing was to make a template of the track alignment and for the shed itself. It straddles a 59” R curve on the layout. Once I had these, I made a foamcore mock-up of the proposed structure so I could test fit it as the layout construction continued. Here are a few photos of this phase

-

Satisfied with the overall geometry, I amassed a lot of stripwood and sheet stock to build the shed. I used 2 different strength mixes of black show dye and isopropyl alcohol to stain all the stripwood before using it in the structure. I opted to stain the sheetwood used for the roof after it was installed to mitigate any warpage issues. I also investigated the quality and accuracy of several makes of stripwood before deciding on Mt. Albert materials.

This is a very complicated structure because of the curvature in it so I developed numerous jigs, and construction aids to help get it right. I built the 5 roof panels first on the base that I had made for the shed. I next built the 2 end sections and the centre sections as separate assemblies and then infilled them with the 2 interior sections. Because I was building it upside down, it was critical that I got the angles correct since the roof is on a 1:5 pitch. I am sure I could write an article on how I built it, so will provide the following photos instead – a picture is worth a thousand words they say!

-

This was the largest model I have constructed in many years and am very pleased with the end result – given how rusty my skills were! For those that like fun statistics, the model contains over 1100 individual pieces, and has close to 16,000 scale feet of lumber in it – not including the roof deck and foundation cribbing components.

Here is a photo of the prototype, and a comparative photo of the completed shed staged in the Styrofoam scenery base. I am looking forward to integrating it into one of the signature scenes on the layout.

- Fall 2018 | CPR Boundary Sub

Scenery Along the Kootenay River Commences

Since we commenced the scenery phase of the layout, we decided the lower deck scene along the Kootenay River that is just inside the room entrance would be another worthwhile location to introduce scenery efforts. Crumpled brown paper “scenery” has occupied this location for many years as a temporary placeholder. Always amazing how long “temporary” things remain on the layout!

-

This is another scene being modelled based on a specific location along the mainline between South Slocan and Castlegar, so we assembled a series of photos to guide us along. You can several of them clipped to the upper fascia in the photos below.

-

We decided to employ the traditional cardboard strip lattice overlain with plaster soaked paper towels in this area. It is fast, easy to revise if necessary and creates an immediate visual impact – even without paint! Over this we installed plaster rock castings using the wet application method. We like this method better since the mold will adapt to the topography of the hardshell easier and look more natural.

-

The plaster castings are painted with a diluted mix of the rock base color of latex paint over which various colors will be added to add visual variety to emulate the prototype. It then will get an application of Mars Black acrylic paint diluted and worked into the cracks and crevasses with a small brush. This is very much an iterative process and will essentially the same process as we are using on the mainline extension referred to above.

- October 2018 | CPR Boundary Sub

REsearch Road Trip

I really enjoy travelling down the Kootenay area of BC and took advantage of the opportunity to do so again this fall. Prior to the trip, I developed a list of specific tasks to do and locations to visit and photograph. This was a follow up trip to the drone photography trip I did in October 2017. See post below.

My objectives included researching the rail bed between Eholt and Grand Forks, revisiting parts of the line between Castlegar and Fife (this was one of the sections we did with the drone), photographing the major multi span bridge over the Kootenay River at Taghum (see prototype photo section) and a visit to the Touchstone Museum in Nelson. It was lot to cram into a 4-day trip; however, it was pretty successful.

Here is sampling of some the photos taken during the trip;

-

- August 2018 | CPR Boundary Sub

Furnace Filter Trees

Well, on a layout the size of, and location of the Boundary Sub, there is a need for a lot of trees – probably a ZILLION I am thinking! Even with the narrow shelf type design employed in many stretches, we are still going to need trees and then – more trees!

Most of the trees used on the previous layout were salvaged, however many more are required, so we build some when the urge or opportunity hits us. This summer we spent a few days at our cabin in the mountains with our friends; Ken & Patty and collectively built a bunch more trees while we were there. Definitely more enjoyable building them with friends, sitting on the deck looking out over the river on a beautiful summer day.

-

- July 20, 2018 | CPR Boundary Sub

Phase 3 of the Mainline

After the conclusion of the RMM meet in May, we chose to take some time off and reflect on what work would be next up for the layout. Given the size and extent of the layout, there is certainly a lot on the “to-do” list, and after studying various projects, it was decided to proceed with the construction of the next phase of the mainline extension. This will take us from the current temporary west staging yard location just east of Farron over to at least Fife, and perhaps even further.

Because this section is on the upper deck over the Nelson divisional yard, we decided it was next because its completion is required before further work can be advanced in the Nelson yard on the main deck below.

To minimize “messy” work being done over the Nelson yard, we have opted to utilize a sectional/modular approach to constructing the upper deck. The intent is to construct and substantially finish as much as possible on these sections in the garage/shop and then install them over the yard. At least that is the theory at this time.

In preparation for this project, we evacuated all equipment and buildings from the Nelson yard, and moved all the locos and freight cars into the East Staging yard. See photos below;

So, we initially developed a mock-up of two 48” long sections made from high density foam and supported on cantilevered metal wall brackets. They were temporarily built and installed for assessment. See the photos below. These were deemed to be too flimsy and somewhat wobbly and the concept was abandoned as a result.

Given our satisfaction with the established strategy of using cantilevered plywood framed sections, it was decided to apply this strategy to this next phase. These sections are quite simple and will be relatively lightweight, so we opted for using ¾” plywood framing and a shallow depth of 2”. Built in 48” long sections where possible, several were done and temporarily screwed to the walls. They are pre-drilled for wiring and future lighting - as can been seen from the photos below;

Future posts will be shared to show the progress of this phase of work.

- May 4 & 5, 2018 | CPR Boundary Sub

RMMBC 2018 Operating Session

We again this year hosted operating sessions for registrants of the annual 7th Division Railway Modellers Meet of British Columbia.

We enjoy a challenge, and tackled several projects to enlarge the layout and improve operations over prior to the sessions as are reported in various parts of this web site and were pleased with the successful implementation of those efforts. Participants from throughout the Pacific Northwest area of Canada and the USA joined us for 2 enjoyable and productive sessions.

Here are a couple photos; for more refer to the Operations Photos section.

- May 4, 2018 | CPR Boundary Sub

Salmo Ore Loading Platform

Loading and transporting ore concentrates from various locations throughout BC and Washington State took place extensively and was shipped to the Cominco operation in Trail BC. These present interesting modelling opportunities as well and realistic operations strategies. One such location was at Salmo BC on the GN 5th Subdivision line from Nelson to the USA which looked like this:

Ken Catlin graciously offered to scratch build this model for the layout. Starting with a wonderful article in the September 1996 issue of Mainline Modeller by Patrick Lawson; MMR, a detailed research program was undertaken to compile data and photos of the prototype structure. With a significant amount of info assembled,Ken redrew the plans for the platform based on the available space – this required a modest shortening of the length as reflected in the following CAD plans he prepared. In addition, he developed the use of numerous jigs to construct the model. Here is a photo of the model and associated plans, jigs, etc. at the 2018 RMMBC meet.

Ken invested an extensive amount of effort in constructing this model, which includes a fully functional loading ramp. This is a wonderful addition to the layout and we are very grateful for his effort. Here are a couple photos of the completed model;

- Spring 2018 | CPR Boundary Sub

East Staging Yard Expansion & Procter Barge Slip Progress

During the early part of 2018, I worked with Patrick Lawson on researching the CPR rail transfer slip and barge operation at Procter BC – east of Nelson. This barge operation was a critical link for the CPR along the Kootenay Lake until the mainline was completed along the west shore in 1930. After that, the barge operation continued serving communities along the north leg of Kootenay Lake, including Kaslo, Riondell, and Lardeau. Here is a couple photos of the prototype after it was taken out of service;

Drawings of this steel slip structure could not be located, so armed with many prototype photos – including some wonderful shots by John Sled of it out of the lake, Patrick developed some plans which we evaluated before settling on a geometry that is close to prototype, but adjusted for model railroad equipment tolerances. This transfer slip is a key component of the design of the east staging yard, therefore, we were now able to complete the installation of the remaining east staging yard tracks. Here is a couple photos of that work being accomplished;

While not exact, the approach tracks to the slip are reasonably close to the prototype, although we had to exaggerate the grades and shorten their lengths to make the geometry work out. There is a lot of prep work to go before the slip can be installed, however, here is a couple photos of it placed on the layout.

-

- January 2018 | CPR Boundary Sub

BC Archives Research Trip, Royal BC Museum, Victoria BC

In the April 2017 post, we provided an update on the construction of the Rossland Subdivision staging yard. With that increased capacity, it became obvious that research on the traffic that was common on this subdivision was required. The huge Cominco plant at Trail BC and other associated mining customers were the main drivers of this traffic.

So, with this in mind, I embarked on a research trip to the BC Archives at the Royal BC Museum located in Victoria, BC. With the help and guidance of renowned author; Robert Turner, I successfully enrolled as a Registered Researcher and spent 2 days at the archives researching the Trail operations. The staff there was extremely helpful (and patient!) and I came away with a significant amount of info and photos. Like many archives, a lot of documents are not digitized; however, they had some useful written lists that greatly helped in locating things.

Bill Dixon assumed the challenge of distilling the data and information I obtained and with his help, and based on the prototype CPR Employee Timetables, an operations scheme was developed for trains to and from this Subdivision. This then allowed us to supplement the loco and freight car fleet in an appropriate manner – in fact, he has loaned over 75 cars to the layout in response to the increased traffic demand! Here is a photo of the added ore car fleet and some of the loads Bill made for them.

The process is not completed yet, and as with any project like this; More research is required!

- October 1 to 4, 2017 | CPR Boundary Sub

drone research trip

My nephew and I spent several days on the abandoned rail line -now part of the Trans Canada Trail (TCT) taking drone and still photos from the end of the operational CPR line just west of Castlegar to Cascade near the US border. This was an amazing experience and resulted in a substantial amount of footage. We are not aware of anyone using this unique approach to “railfan” a railroad line.

I must point out that this work was done with the express permission of the Columbian and Western Trail Society who maintain this section of the line under agreement with the Provincial Government. We had to file papers for approval and my nephew is a trained professional drone operator. Drones can be extremely dangerous and must be operated under the strictest controls by skilled operators. Some of our work will be posted on the trail societies’ web pages in the coming months for educational and promotional purposes.

A drone’s vantage point can easily be set to emulate the viewing angle that a modeller has when viewing a layout, so we ended up with a lot of material that will assist us when constructing this section of the layout. All major tunnels and bridges remain in service as part of the TCT, several of which are included on the layout, so this was a wonderful opportunity to film them for posterity.

There is a huge amount of footage to still process, however, we offer the following as example still shots of what we captured. The videos still need to be edited and then will be posted and provided to the Trail Societies. Watch for updates on this in 2018.

- September 8 to 10, 2017 | CPR Boundary Sub

vanrail 2017 op sessions

As part of this biennial invitational operations event, the Boundary Sub again hosted 3 back to back sessions over the 3 days as well as the Friday evening social which was attended by close to 80 people. This was the second VanRail event for the new layout and we were very pleased with how it performed. This would not have happened without a lot of help from my home road crew!

This year’s event had a record number of guests, and layouts, and we were very pleased with the participation and interest in the event.

Here are a few photos taken during the sessions, for more refer to the Operations Photos section:

- August 22, 2017 | CPR Boundary Sub

nelson diesel shop arrives!

This iconic structure was an essential building to include in the Nelson divisional yard, and I was thrilled that Patrick Lawson, MMR offered to construct it for the layout. His plans and article on this facility were published in the December 1996 issue of Mainline Modeller which gave us a solid starting point for planning the building.

While the yard has sufficient space to accommodate all 4 tracks, the building length needed to be reduced somewhat due to space constraints at the east end of the structure. After experimenting with various combinations, we settled on a design that was 80% full length while still retaining the overall character. Most people familiar with the prototype would not notice the reduced length.

Because the prototype had a huge number of large windows, especially on the side facing the main aisle, we concluded that the interior where tracks 3 & 4 are located needed to be detailed since it was so easy to see. Patrick developed a technique of constructing a Plexiglas shell for the entire superstructure onto which he laminated 3D printed window/wall panels. He also 3D printed all the roof trusses, overhead crane gantry, mechanical ventilators, handrails, and numerous other parts.

Tracks 1 & 2 were the run through tracks where locomotives received only light servicing and are less visible on the model so that area of the building will not be detailed except close to the large overhead doors. However, the tracks in this area ran on elevated steel framing which created a pit under the entire area – so, the model base had to accommodate that depth. As a result, the base was constructed separately and is designed to be recessed into the layout by 1.25”. This also allows the superstructure to be removed for access to the building interior should we need it. Here are a couple of photos with the base placed on top of the new dropped plywood subbase:

While not fully completed yet, this building is still a commanding structure on the layout. It is now my job to complete the layout framing modifications. And then paint, weather and complete the final detailing as well as interior and exterior lighting for it. Watch for future posts showing the final installation and completion of the trackwork. Meanwhile here are a couple of photos of the overall building

- August, 2017 | CPR Boundary Sub

south slocan turnout controls

This particular location has always presented a challenge to operators because of the wye configuration and the distance to some of the turnouts from the main aisle. I wanted to address this before the upcoming VanRail event, so we tackled in a similar manner to the previous work done in Castlegar. See the entry below titled; Spring 2017 | CPR Boundary Sub Turnout control installation.

Tortoise machines were installed for all the turnouts and controlled by “drivers” and two temporary control panels were constructed. The control panel geometry was a bit tricky, so I did up some trace paper mock ups to allow us to visualize how they would work out. The temporary panels will eventually be replaced with better quality ones that will probably be recessed into the fascia.

- August, 2017 | CPR Boundary Sub

more fascias & backdrops!

In preparation for the VanRail 2017 event, we decided to install and paint some more fascias and backdrops. Adding them is relatively easy and really has a significant visual effect on the layout. I was fortunate to have the assistance of Ken Catlin and John Martin to complete this work.

-

There are a few sections where the geometry is a challenge, so we elected to mock some fascias up using corrugated cardboard. It is cheap and we can trim it or even replace it if it doesn’t seem correct.

- July, 2017 | CPR Boundary Sub

electronics system upgrades

I am the first to admit I am NOT a tech guy, so when it came time to replace the electronics cabinet with a larger one capable of housing all the equipment necessary to support the ultimate layout, I reached out to several members of my home crew to assist me.

-

The layout had reached the point where the existing DCC system and breakers were being taxed, and we thought we had better rectify that before it decided to quit – which, as we all know – would happen during an op session! -

So after assessing how many boosters, power supplies, breakers and reversers would be needed for the eventual complete layout, we then added more to be safe. Then we dismantled the old cabinet and stripped out all the electronic stuff. Based on the new requirements, I designed and, with the help of Ken Catlin, built a custom new cabinet to house everything. The new cabinet was put on casters to make it easier to access the rear where a lot of the bus wiring comes in. we also have a small fan to cool the command station, boosters and power supplies - a couple of local guys have experienced some overload to their DCC systems due to heat. -

Although there is space for everything, we only installed part of the equipment at this time – partly due to budget constraints! - July, 2017 | CPR Boundary Sub

110 Volt wiring additions

When we built our home several years ago, I had the contractor rough in some additional circuits out of the layout room sub panel for future use. Now that the majority of the layout main deck and associated pony wall framing is completed, it became time to extend those circuits into the walls and ceiling areas.

-

In total, we added 12 duplex outlets around the layout support walls, 3 junction boxes in the main layout peninsulas to feed the planned under deck lighting, and several more junction boxes located conveniently in the ceiling. -

The room was quite a mess during this work as can be seen from these couple photos, however, we had it all back together before we resumed operations in August.

- May 5 - 6, 2017 | CPR Boundary Sub

RMM 2017 Op sessions

Operations is a fundamental objective for the layout, and we are therefore, always pleased to host operating sessions for registrants of the annual 7th Division Railway Modellers Meet. The dates for this event were recently revised from November to May, and as a result, the Boundary Sub and several other local layouts hosted sessions with only 6 months between the 2016 and 2017 events.

We enjoy a challenge, and tackled several projects to enlarge the layout and improve operations over that 6 month period and were pleased with the successful implementation of those efforts. Participants from throughout the Pacific Northwest area of Canada and the USA joined us for 2 enjoyable and productive sessions.

Here are a few photos; for more refer to the Operations Photos section.

- April, 2017 | CPR Boundary Sub

Newest crew member

Wren Emilia Calvert, born in Australia on April 14, 2016 and recently moved to Canada, has joined the Boundary Sub project team as the youngest member. While she cannot reach any of the actual layout, and has only recently started to walk, she is providing valuable advice and input related to the need to increase capital investment in equipment to keep pace with the physical expansion program. We also anticipate she will be providing critical IT support services – once she learns how to talk!

- April, 2017 | CPR Boundary Sub

CPR Rossland Subdivision staging yard

Early this month, this important staging yard was placed into service on the layout. Originally conceived to be located in a storage closet in my wife’s adjacent quilt studio, and affectionately referred to as “Quilt City”, a redesign and some modifications of track alignments in a couple of places yielded a more practical location in the separate part of the layout room where the Dispatcher is located.

This yard was constructed using the typical plywood “module” approach we have used for other areas of the layout which would allow it to be slid out of its position in the future should we need to do so. In addition, all the pre-wiring of bus and feeder wires was completed while the module was on its side before it was installed.

Connected to the mainline at Castlegar, the prototype Rossland Subdivision provides service to the large Cominco plant at Trail, BC. At 6 tracks, this yard is designed to handle a representative flow of traffic to and from this customer as well as ancillary industries in the area. We are slowly increasing the freight car fleet and introducing appropriate trains into our ops scheme to reflect this addition to the layout. Ongoing research is underway in studying the types of cars and loads that are to be modelled.

Here are a few photos; for more refer to the Layout Photos section.

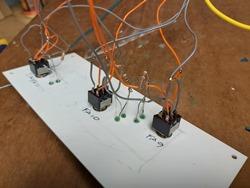

- Spring 2017 | CPR Boundary Sub

Turnout control installation

As part of the revision and upgrades to both Castlegar and South Slocan, it became necessary to install turnout control switch machines in numerous locations. These would be the first to be installed on this version of the Boundary Sub, but not the last by far. Tortoise slow motion machines were selected primarily because I have a large number of them in stock. We are also quite interested in the much smaller and more affordable MP1 & MP5 ones distributed by Model RailRoad Control Systems; http://www.modelrailroadcontrolsystems.com/ and recently purchased several to experiment with.

Adopting the philosophy that if things are constructed to be easily removed for maintenance, it will probably never have to be done, we set about developing a universal mounting bracket with some placement tolerance, and we also wanted a wiring connection that was also easy to disconnect.

In my opinion, the Tortoise machines provide virtually no tolerance for installation to the underside of the layout. We wanted to have tolerance in both the lateral and longitudinal directions to make the installation work easier. Also, because spline roadbed is used for a lot of the layout – which is quite narrow – we needed to develop a mounting strategy to account for the fact that the Tortoise is wider than the spine system. As always, I reached out through the net and asked folks for their thoughts and opinions, and was very pleased with the feedback I received. I have to admit that some of the installation techniques were very unique and I felt that some may be problematic over time. On a large layout like the Boundary Sub, we work hard to make things as reliable and bullet proof as possible.

I also found a really neat 3D printed mounting bracket online and ordered a couple for research purposes. Here is the link if you are interested; https://www.thingiverse.com/order:8581 While pretty slick, they only offered tolerance in one direction and are quite costly by the time the currency exchange and shipping costs are factored in. So, we proceeded to develop our own by trying out several cardboard mock ups for possible configurations. The final mounting plates are made from 3/8” cabinet grade plywood – actually scraps from the roadbed for the helix – see the February 8. 2016 entry below. See some photos below.

We also wanted a wiring harness that could be easily removed should the machines fail or in case modifications were required. So, with the help of Doug Hicks, we soldered female plug assemblies on to the machines, and a wiring whip on the male end of the plug as can be seen in the photos.

- January / February 2017 | CPR Boundary Sub

Castlegar Yard Improvements

In anticipation of the introduction of a staging yard which would represent the Rossland Subdivision in the near future and in recognition of the congestion and confusion that takes place in Castlegar during op sessions, we undertook numerous revisions to the yard area.

Up until now, the wye was incomplete and the yard tracks were somewhat awkward and inefficient, and these needed to change. There was also an opportunity to add more local switching locations.

So, the dead end portion of the yard tracks were removed so accommodate a reconfiguration that would allow them to become double ended. This required modifications of several Shinohara curved turnouts and the installation of a reverser circuit breaker by DCC Specialties.

The reconfigured yard tracks and newly completed wye would connect to, and feed the Rossland Subdivision staging area. The new turnouts were beyond reach and required the installation of slow motion switch machines and an associated control panel. Because of the desire to have consistent switch machine controls on the layout regardless of where they are, we chose to operate the machines by a push button and not a toggle switch. After some research, we settled upon using circuit board “drivers” manufactured by Ron Paisley; http://home.cogeco.ca/~rpaisley4/3556StallAltern.html

We will address the actual switch machine installation and operation process in the next posting.

Here are a few photos showing the revisions to the Castlegar area.

-

- November 3 - 4, 2016 | CPR Boundary Sub

RMMBC Op sessions

One of the highlights of the annual modellers meet here in Vancouver, is the operating sessions which I have coordinated for many years. The Boundary Sub (both current and previous versions) has been one of the layouts included in the offering and we really enjoy hosting guest sessions. As most operating layout owners know, a great deal can be learned from guests that are new to your layout and operations scheme. Their perspective can be quite illuminating.

-

This was the first opportunity for new folks to operate the layout with the 130 foot mainline expansion that was completed earlier this summer. In fact, we only hosted three home crew sessions on the expanded layout before welcoming the RMMBC guests. A little blind faith never hurts in these circumstances!

Each session had 8 guests participate and their Ops skills ranged from “newbie” to “experienced”. Regular crew member; Rene Gourley kindly dispatched both sessions with his usual skill, and Ken Catlin provided veteran home crew support for the visitors, and as a result things went very well under their guidance.

Here are a few photos of the session.

- October 12, 2016 | CPR Boundary Sub

nelson Superintendents house

In 1911 the CPR constructed a beautiful residence for the Superintendent of the Kootenay Division on an embankment just above and to the immediate east of the Nelson station building. The residence has had several occupants – railroad and otherwise, over its lifetime and is considered a heritage structure and has been preserved with few revisions. This house typifies many of the premier homes that were constructed for railroad executives all across Canada. A recent photo is included here.

In 1911 the CPR constructed a beautiful residence for the Superintendent of the Kootenay Division on an embankment just above and to the immediate east of the Nelson station building. The residence has had several occupants – railroad and otherwise, over its lifetime and is considered a heritage structure and has been preserved with few revisions. This house typifies many of the premier homes that were constructed for railroad executives all across Canada. A recent photo is included here. -

The initial plan for the layout contemplated a location for this building which is relatively geographically accurate. The Cottonwood Creek passes through a small green space between the station and superintendents house. Planning for the area in and around the station proceeded and needed to include the superintendents house and various other elements as well. -

Patrick Lawson MMR prepared and published some excellent plans for this wonderful building as part of an article in the April 1998 issue of Mainline Modeller, and to my delight, Patrick graciously offered to construct this building for the Boundary Sub. It makes a great companion to the station building he also built for the layout. (refer to the NELSON STATION MODEL entry below). -

By building a cardboard mock up using the plans I determined that there was not quite enough space to accommodate the full depth of the building. A little experimentation which considered the overall topography and configuration of this area allowed the appropriate depth to be finalized and the mock up was modified for confirmation. (see photo).

By building a cardboard mock up using the plans I determined that there was not quite enough space to accommodate the full depth of the building. A little experimentation which considered the overall topography and configuration of this area allowed the appropriate depth to be finalized and the mock up was modified for confirmation. (see photo). -

A copy of the plans were then marked up and supplied to Patrick who then embarked on building a beautiful model of this locally recognizable residence. As a MMR, Patrick employed several techniques, including 3D printing several components, to complete the model. It was painted in colors that are appropriate for the 1960 era. A photo of the house temporarily positioned is included here. Much scenery and other work needs to be completed before the structure can be permanently located.

- October 4 - 7, 2016 | CPR Boundary Sub

Research Road Trip

In July 2015 I had a very successful trip exploring portions of the railroad that I am modelling. At the time, a further trip was determined to be necessary, so off I went again in October of this year. My travels took me to Nelson, Salmo, South Slocan, Castlegar, Paulson pass and Grand Forks – a lot of territory to cover in 4 days.

In July 2015 I had a very successful trip exploring portions of the railroad that I am modelling. At the time, a further trip was determined to be necessary, so off I went again in October of this year. My travels took me to Nelson, Salmo, South Slocan, Castlegar, Paulson pass and Grand Forks – a lot of territory to cover in 4 days.