-

layout photographs

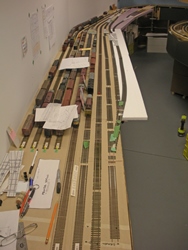

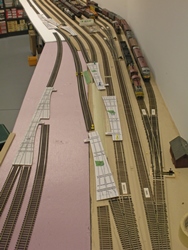

One of the main objectives for this layout was to achieve and maintain an operations capable layout during its construction, which means that the construction is continuously progressing in phases.

Each project is focused on accomplishing a specific objective towards improving or expanding the ability to operate the layout. Typically, most major phases are motivated by an upcoming operations event such as VanRail or RMMBC.

The posts below are a sample of various stages in the work, so check back often as we continue to update this section.

-

February 2024; Layout Progress Photos

-

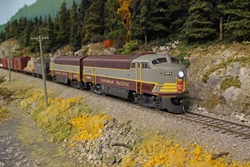

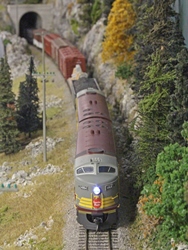

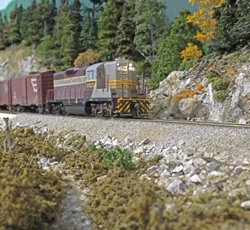

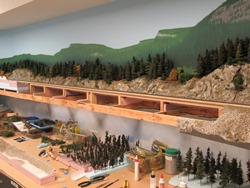

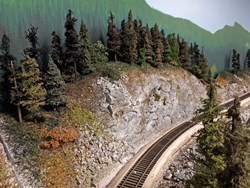

Below are a few photographs of the sceniced upper deck of the layout including Farron and the Paulson area near the summit of this section of the Boundary Sub.

-

February 2023; Layout Progress Photos

-

Below are some recent photographs of the relatively completed areas of the layout along the upper shelf above Nelson.

Photo taken by Margot Calvert.

-

Below are some recent photographs along the Farron upper deck shelf. While there is still some work required to complete the scenery in Farron, however, I am quite happy with how things look so far.

-

June 2021; Layout Aisle Photos

-

In June 2021 I prepared these overall layout photos to be included in the Virtual layout Tour video I did for the 4th Division, PNR, NMRA. They are intended to provide a overview of the layout from the various aisles.

-

Summer 2020; Upper Deck Progress Photos

-

Fall 2019 & Spring 2020; Upper Deck SCenery

-

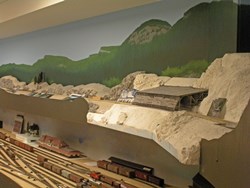

The last update on this project was in Summer 2019 below, and since then we have tackled a lot of progressive finishing steps towards completion of finished scenes. While there are always various small items to attend to, we are getting “close enough”, so offer the following.

We needed a LOT of rock talus for the layout and I wanted it to blend with the colors of the rock castings, so we undertook making our own talus from scrap plaster castings. They were crushed, sifted and sorted into sizes. They were colored by immersing in a thin mix of the various latex paint colors than were used on the rock castings and then spread out on heavy duty paper towels to dry. We usually left them for several days to ensure they were completely dry before using the materials.

-

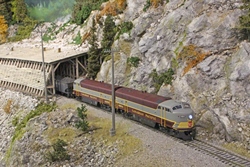

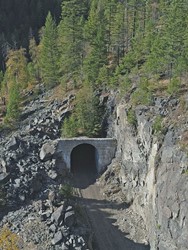

A custom mix of several colors of Woodland Scenics fine ballast was created to blend with the colors of the rockwork and talus in the area. Once the previously sceniced landforms were glued in place, the gap between them and the roadbed was sealed using a DAP grey coloured caulk. The caulk was smoothed out and some sand was pushed into it before it dried. This gives the subsequent ballasting something to bind to. Then the adjacent scenery textures and colors were extended and blended into the ballast.Integrating the cast portals and liners for the Paulson tunnel was a tricky project, particularly because we wanted to replicate the look of the prototype ones as closely as practical. As reported in the June 2019 What’s New post, these concrete portals and associated liners were all cast using a custom fabricated mold.

Because there are sight lines into the tunnel, we also made several rock liners using the Woodland Scenics plastic mold. These were sanded and then glued together using carpenters glue. We then strengthened the assembly with plaster gauze laid over them. The rock liners were given a spray of flat black paint to create a visual depth to the tunnel.

Positioning the portal assemblies and fitting them into the plastered landforms took a fair bit of effort, however, the results are quite satisfying.

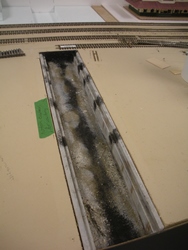

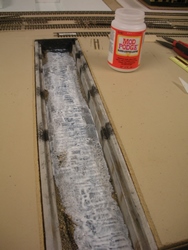

There is a really interesting scene that we wanted to emulate where McRae Creek runs adjacent to the mainline track. Depending on the time of year and amount of rainfall, this creek can be more like a bog, and we choose to model that look.

Two 4 foot long landforms make up the length of this creek, which were prepared and sceniced employing the typical techniques used elsewhere. These landforms were then permanently installed on the layout. The actual creek bed received a layer of gravel and fine sand and then was painted with acrylic paints in dark colors to match the prototype look. We choose to create the calm water by applying many coats of gloss MOD PODGE. The scenic materials were brought down to the water level just prior to the last couple of coats being done. To create the grass and weed on & in the water look, we carefully dusted the last wet coat of MOD PODGE with a mix of ground foams and static grass materials.

-

-

March 2020; Farron Siding Structures

-

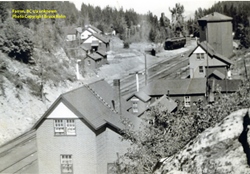

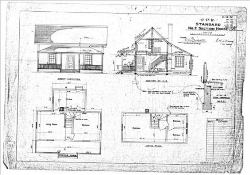

Farron was the Monashee Mountain summit on the line between Castlegar and Grand Forks, BC and was the base for the CPR helpers that worked the grades on either side of the pass. In my chosen era, there were only a few railroad structures located here. I am fortunate to have some photos and prototype CPR plans for many of the buildings. The most obscure structure is the combined station/residence building that served this location until the abandonment of the helper services.

The challenge here is that the cluster of buildings is located on the aisle side of the shelf and therefore required an increase in the depth of the deck from 12” to 18”. Several mock ups were made using foamcore and arranged to emulate the prototype the best I could, which in turn determined how long this upper deck extension base needed to be. The current intention is that the Styrofoam base for this area will be removable so it doesn’t get in the way when we are working on the layout.

To date, the two section house mock ups are built and the Fife water tank model (built by Patrick Lawson) is being used as a stand in. Once I obtain some more photos of the station, I will make a mock up for it as well.

Here are a few progress photographs and copies of the prototype plans for the section house and 40,000 gallon enclosed water tank.

-

-

Spring 2020; Farron Scenery

-

The track in Farron was installed just prior to VanRail 2019 so we could use the newly extended mainline. There has been no further work on this area until recently, when I decided it was time to continue scenic efforts through this area and blend it with the adjacent scenery that was nearing completion.

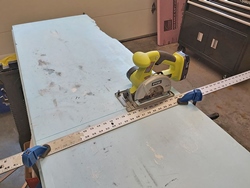

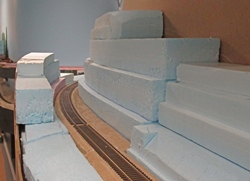

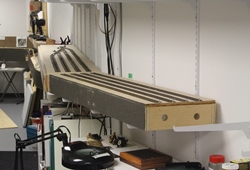

Being on the upper deck and directly over my workbench area, we again elected to use the Styrofoam landform methodology as was being used elsewhere to minimize the mess in the actual layout room. This area includes about 25 feet of 12” deep deck and the actual wye area as well. The topography is much less rugged than what I have been dealing with to date – which was a welcome relief!

The landforms are completed and have received the necessary rock castings and base plaster coat for now. The scenic texturing phase on these landforms will be undertaken in the coming months using materials and colors similar to those utilized on the adjacent completed scenes because Farron is in the same valley.

This area also required some additional fascia construction and modifications, as well as installation of the necessary backdrop to cover the metal wall shelving bracket system. Plywood strapping was glued to the wall and 24 feet of 1/8” hardboard panelling was installed. All joints and screws were mudded and sanded after which the entire length received a coat of primer followed by a coat of the standard sky blue latex paint. Further backdrop paining will be undertaken in the coming months.

Before proceeding to complete this area, all the turnout switch machines and controls need to be installed and tested. We are now undertaking those tasks.

Below are a series of chronological photos capturing the general efforts to date.

-

-

-

September 2019 Progress Photos

-

Here are a series of progress photos of the layout to date. Lots of work to do, however, these provides a sense of what our objectives are. They are just a sample of various scenes around the layout.

-

-

Summer 2019; Upper Deck Scenery Continues

-

Work on the upper deck scenery commenced in the fall of 2018 once the framing concept had been finalized for the cantilevered modules that would support this next phase of the layout. As reported elsewhere, we elected to build the scenery using Styrofoam landforms over which we applied a base coat of plaster with rock castings where appropriate, and then a variety of scenic textures and materials.

This process was interrupted twice to accommodate hosting operating sessions for RMMBC in May 2019 and VanRail in September 2019 when the layout was restaged to accommodate these sessions. In late September, we once again decommissioned the layout so we could continue towards the completion of the scenery for this part of the layout. As of the writing of this post, it is our intention to complete the scenery before recommissioning the layout for further operations. This is anticipated to occur in early 2020.

It has been a time consuming and iterative process to advance the scenery along for this phase with a lot of trial and error and relearning of scenery skills. There was also a lot of research that went into this phase because we are trying to emulate specific scenes on the prototype rather than creating generic scenery.

The construction of this upper deck now creates shadows on the lower Nelson yard area, and we are now in the early stages of researching lighting solutions to install under the upper deck. This will be the first section of the layout to receive this lighting so we want to get it “right”. There is approximately 300 feet of upper deck that will need lighting installed below it.

A great deal of effort has been invested in this work by my home crew; Ken C, John M, Bill D, and Rene G. without their help, the progress would not be where it is so far. We are pleased with the outcome and feel that the scenery is looking very realistic.

Here is a variety of photos of the work:

-

-

Summer 2019; Phase 3 Mainline Completion

-

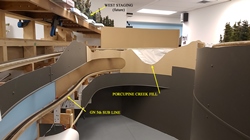

The After hosting operating sessions for RMMBC 2019 in May this year, we shut the layout down again and resumed work on the upper deck mainline extension with the objective of having it functional by VanRail 2019 in early September. We built as much of the framing and spline system as possible, and then dismantled, modified and reinstalled the 12 ft long temporary west staging yard in the next location for it.

Once the temporary staging yard was removed, we infilled its location with several prebuilt plywood framed modules. This allowed us to connect the end of the existing mainline with the other new modules that had been installed over the Nelson yard to date. Once that was completed, the spline roadbed system was installed and prepared for the trackwork. This work included the use of cork to create a slightly higher mainline. The phase of work used the same methods used throughout the layout.

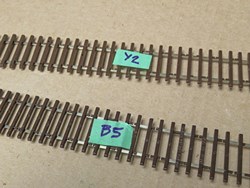

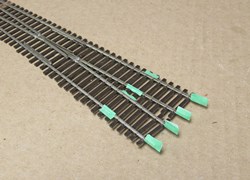

All the turnouts are Shinohara code 70 that were modified to be more DCC friendly, and all the flextrack is Micro Engineering code 70. All the flextrack was laid out and shaped very carefully so I would not need to manipulate it much when it came to installing it. Each piece of track was labelled with corresponding labels placed on the roadbed so we could keep track of which pieces went where. The track was prepared for painting and then airbrushed and weathered using a combination of Floquil and acrylic paints. This is the first section of track on the layout to be painted and weathered, so this was another learning curve process for me. Once the track paint had dried, it was installed in the same fashion as the previous trackwork on the layout.

The final steps required to complete this phase were to design and construct the vertical lift bridge that spans across the room entry door, connect the track to the relocated staging yard, and test it all. The lift bridge was engineered by Ken Catlin (who did the swing gate on the lower level) using heavy duty 20” travel drawer glides and a piece of aluminum T shaped extrusion I scavenged many years ago. A temporary piece of 2x3 with hardboard gussets was used for the bridge part to test the alignment and ease of the vertical travel. Once satisfied, the permanent bridge was constructed using plywood gussets between the drawer glides and the aluminum extrusion. After some tweaking, the track was then installed over the bridge and into the staging yard. The final step was to actually run a train over it!

-

-

Spring 2018 East Staging Yard Expansion

-

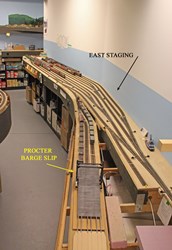

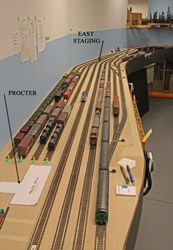

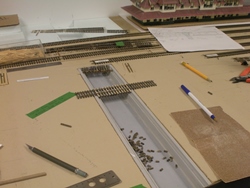

The receipt of the wonderful model of the Procter transfer slip structure from Patrick Lawson prompted us to complete the trackwork for the east staging yard – which includes the Procter BC transfer slip location. Having he actual model greatly assisted in working out the geometry of the new tracks.

-

This staging yard is actually a combination of a staging yard representing eastern destinations, and the actual location of Procter, BC located on the CPR mainline east of Nelson.

-

A partial yard has been in operation since we commenced operations on the layout many years ago. It was now an opportune time to finish it off from a track perspective. Plus, having the transfer slip allowed the inclusion of some interesting prototypical operations.

-

As is typical, we did various mock-ups of the track and possible framing additions, playing with the desired objectives against the available space. Even though this is less “busy” area of the layout, we wanted to minimize the reduction of the aisle width.

-

The completed yard was put into service during the 2018 Railway Modellers Meet – you can see photos of it in the Operations Photos section of the web site.

Here are a series of photos showing the progression of the work;

-

-

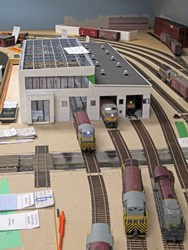

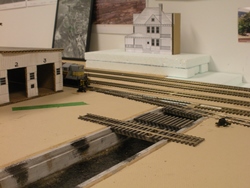

Fall 2017 Nelson Diesel Shop Base Installation

-

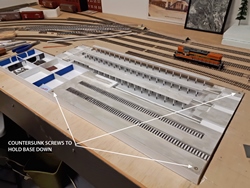

This structure was constructed in 1955 to accommodate the necessary servicing for the diesel locomotives that were being introduced into the Kootenay area. Our model required the layout top to be lowered 1.25” to accommodate the depressed pits.

After finalizing the track configuration on both sides of the shop building as noted in the previous entry, we removed and lowered the necessary section of framing and employed multiple screws to hold the base down, and most importantly, allow us to remove it to complete surrounding work, and for future work.

The following photos show some of the effort required to complete this work. -

-

August 2017 Nelson Diesel Shop Track Configuration

-

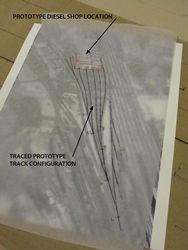

To allow finalizing the exact location of the diesel shop, the configuration of the tracks on both sides of the building needed to be determined.

Using an enlargement of an aerial photo of the yard, I sketched the prototype tracks on a trace paper. This was compared with the actual track configuration shown on a yard plan that I have, and armed with this, I proceeded to try various track and turnout configurations to see how close we could get. Once satisfied with a layout as close as possible, the tracks and turnout locations were marked on the roadbed and the position of the diesel shop was confirmed.

The following photos show some of the steps for this process;

-

-

April 2017 cpr rossland subdivision staging yard construction

-

This prototype subdivision was very busy and generated a lot of traffic for the CPR, particularly in the early years. CPR timetables in the late 50’s and early 60’s showed several trains going in and out of this subdivision daily! It was determined during the earliest planning stages for the layout that this would be modelled as a staging yard, although the exact location and design was not established at that time.

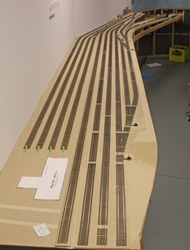

The following series of photos provides a progressive overview of the construction and implementation of the 12 foot long, 6 track Rossland Subdivision staging yard. The turnouts will have switch machines installed and we intend to use a power routing strategy to align them and also provide power to the tracks. This work will be completed this summer.

-

-

Dec 2016 to Mar 2017 - Nelson west modification

-

One of the unique elements at the west end of the Nelson yard is the two curved tracks that the railroad used for cleaning out various freight cars. These tracks were typically quite full and usually had a debris field around them – particularly in the earlier years.

After mocking up numerous configurations on how these could be incorporated into the available space on the layout, we compromised a bit to maximize the length of these tracks at the expense of the turnouts being in exactly the correct prototypical arrangement.

We then proceeded to remove several existing turnouts that needed to be modified to be DCC friendly and we also removed a spur that was installed during the original yard construction but was not really correct and would interfere with future scenery objectives in this area.

We are quite pleased on how this modification turned out, and it has certainly added to the Nelson yard work load.

Here are some photos of the work and completed configuration. -

-

august 2016 progress photos (Fascias)

-

-

august/September 2016 progress photos (cOTTONWOOD CREek)

-

The channel has been painted and debris installed along the bottom of it. Overall view of the channel with a couple of the short timber “bridges” being test fit across it to carry tracks to the diesel shop building. This shot was taken by Mike Barone in the 1990’s and shows the channel quite clearly. Many of the “bridges” across it are now removed due to ongoing abandonment of the rail facilities located in Nelson.

-

june/july 2016 progress photos

-

Here we see Ken C lifting up the 12 foot long temporary west staging yard module after we have removed it in preparation for the mainline extension.

We separated the staging module into a 4 foot and 8 foot section, and here we see the longer one on its side so Ken C can complete some wiring revisosns to it prior to it being reinstalled at the next location. This shows the temporary west staging modules reinstalled. Note that there is a bend in them to accommodate the wall angle. This is why we separated it into an 8 foot and 4 foot section.

Here we have installed the 66” long drop module to support the McCormack Creek trestle. We are using the cardboard trestle mock up to verify geometry. Here we are installing the new spline roadbed west of Castlegar.

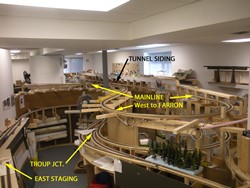

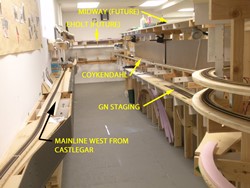

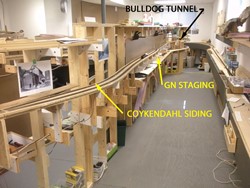

This is a view looking down the aisle west of Castlegar where we are installing the tracks to reconnect the mainline. Coykendahl siding can be seen on the upper right of the photo.

May 2016 progress photos

-

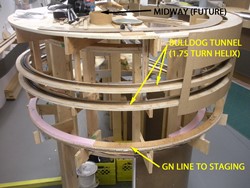

Refer to the plans of the two decks of the layout located under the LAYOUT tab of the web site for help in understanding where these photos were taken.

-

-

SEPTEMBER 2015 progress photos

-

-

-

April 2015 progress photos

-

-

-

january 2015 progress update

-

-

-

early layout framing

-

-

.jpg)

.jpg)